3D Printing Ceramics

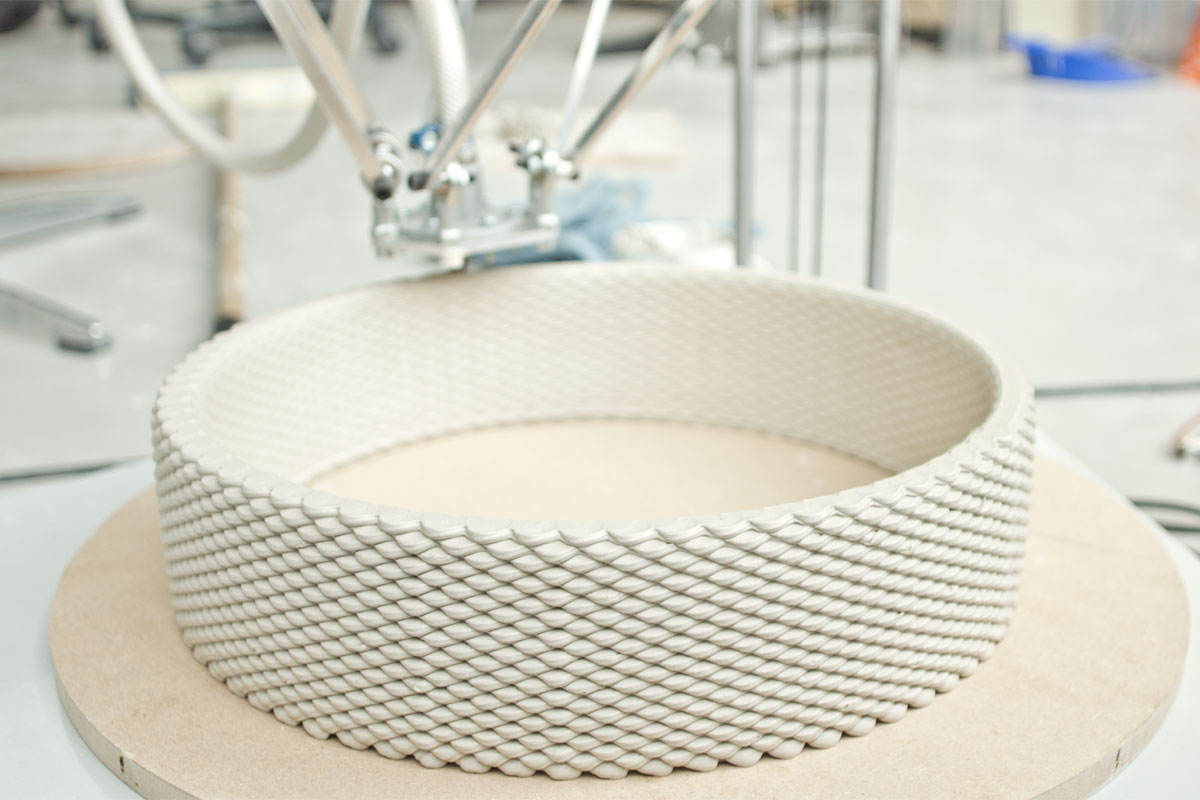

When I first started researching 3D printing the technology was an exciting and interesting one. But, the desktop 3D printers on offer were unable to produce things at a human scale. Large and medium scale functional design objects that we use such as bowls, plates and decorative objects could not be made.

The objects made with desktop 3D printers were also low in heat resistance and could not be food safe. Industrial 3D printers could make food safe objects for everyday use but these would be too costly to produce. I ended up spending years working on a ceramic 3D printer and 3D printing process that could make large and medium scale functional 3D printed ceramics to solve this problem.

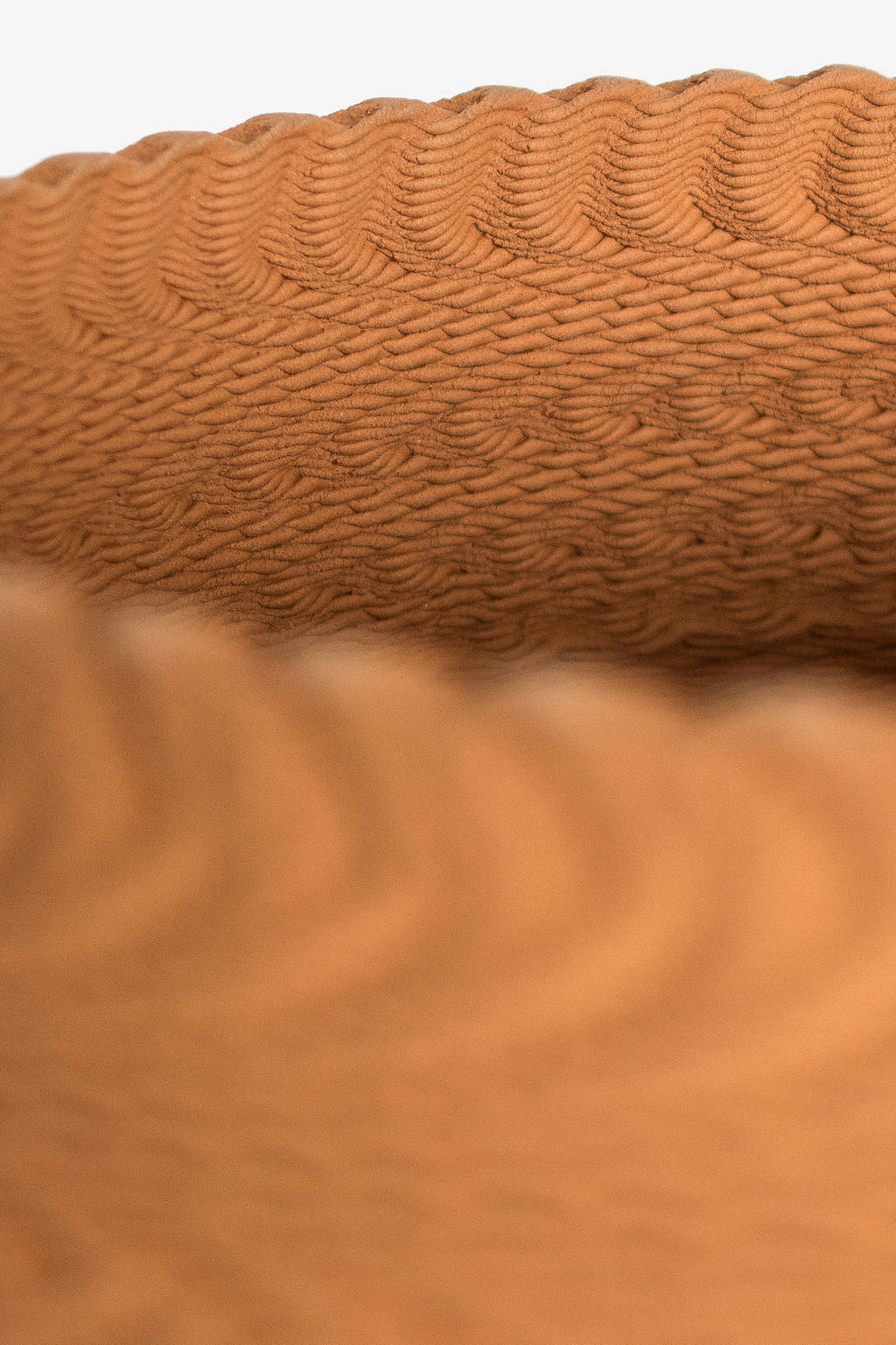

I designed and made my own clay extruder and experimented with many different types of clay. Iteratively improving my process and testing brought me closer and closer to a solution. I gradually solved major issues such as the collapse of objects. A breakthrough came when I decided to move from mixing clay with water. By redesigning my extruder I could use hard clay instead. This lead me to be able to make larger objects with higher levels of detail.

In the early days the 3D printed ceramic vases and bowls seemed rough, with the layers clearly visible. I was able to experiment with textures, surfaces, shapes and sizes. Now I'm able to make objects up to 80 cm tall with a diameter of 42 cm. By altering the settings on my machine I can vary and give the pieces very different appearances.